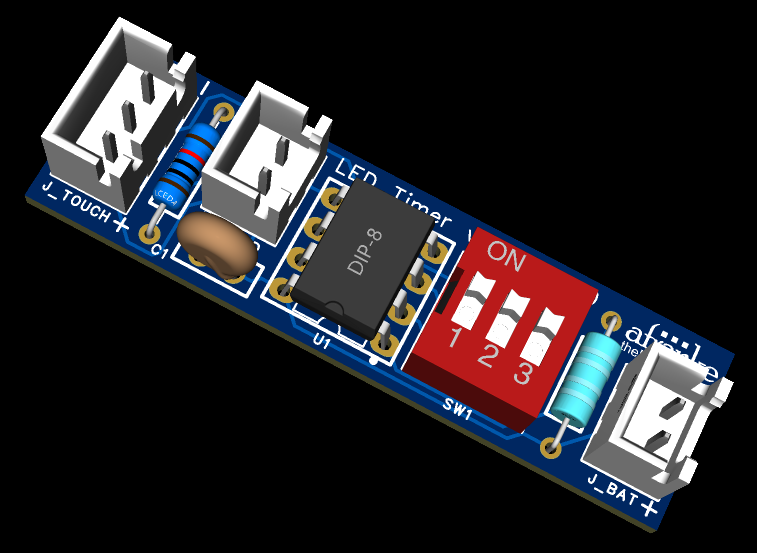

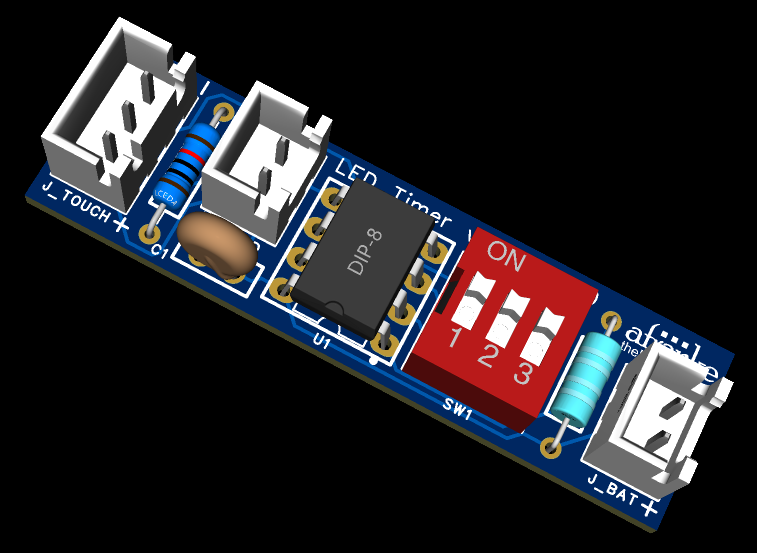

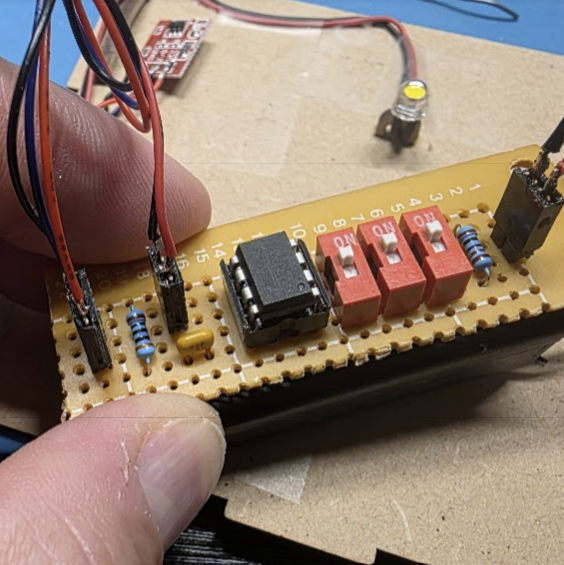

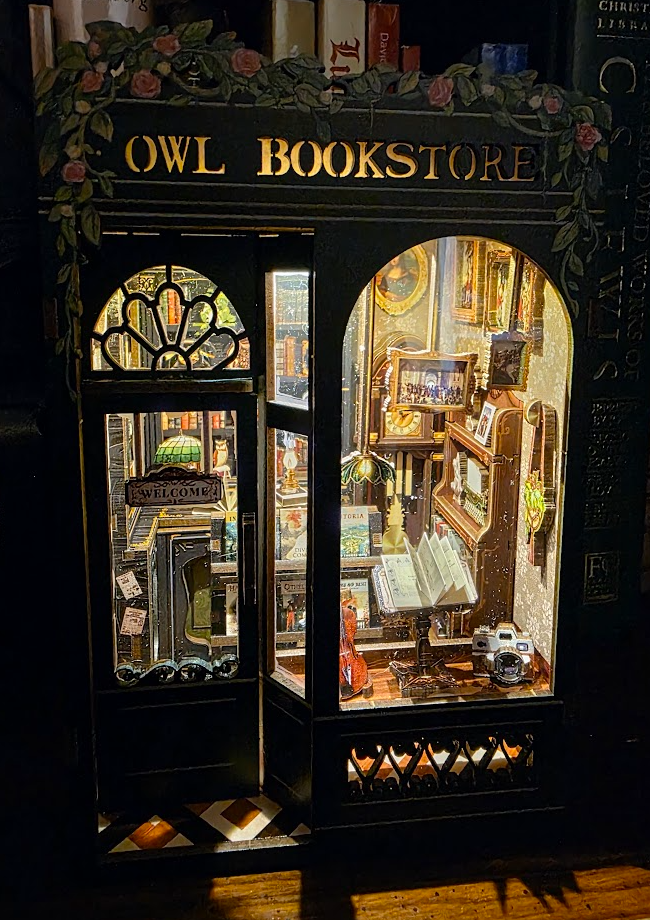

The Circuit: Designing for Low Power, Clean Logic, and Physical Constraints In Part 1, I explained why I tore out the original “transistor-and-hope” lighting circuit from my Book Nook kit.In Part 2, I went through the firmware architecture around watchdog…