Welcome to theFrankes.com!

Welcome to theFrankes.com. This blog has been around for decades now, and I do have a full-time job and family, so please be patient as I get it back up to modern standards. It’s a long, slow process that competes…

Welcome to theFrankes.com. This blog has been around for decades now, and I do have a full-time job and family, so please be patient as I get it back up to modern standards. It’s a long, slow process that competes…

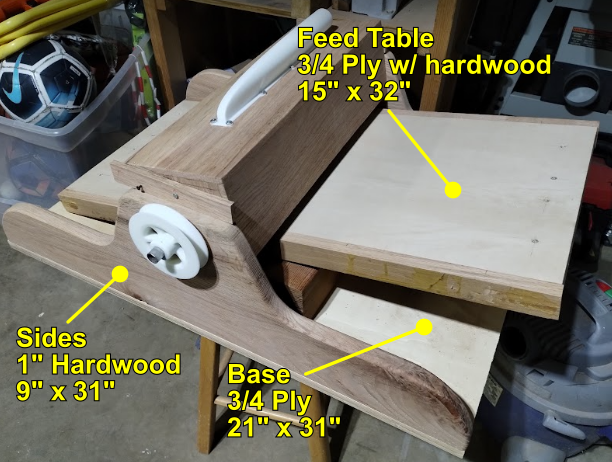

Backstory: We took down a red oak a couple years ago (Part 1 and Part 2) and I got it milled up for projects. Wifey wants a desk but the grain is a little tricky and my thickness planer just…

I got the Viofo A129 Duo a couple years ago because I seem to keep getting cut off in my little Mazda MX-5 Miata ND (2016+). It’s a ragtop convertible with only one obvious place to mount a rear-facing camera,…

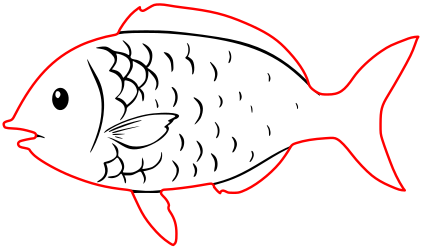

Here’s how I start with a screenshot (bitmap) of a vector image and prepare it for laser cutting. Usually for cutting I need one path around the outside of the image (for the cut path), and then other paths that…

I use ESPHome for a number of projects including LED task lighting, and my devices often use an inexpensive TTP223 capacitive touch sensor as a button. I like to be able to tap the sensor multiple times to cycle through…

I use inexpensive TEMT6000 sensors in various projects to detect the level of ambient light. I originally hand-coded the firmware, but now I use ESPHome. My projects are usually 3.3V because I use pretty bare boards like ESP-12F instead of…

I’m using ESPHome with Home Assistant for a bunch of home automation projects. I want to be able to flash some of the lights in a Morse code “SOS” pattern as an annoying alert that something has gone terribly wrong.…

I have a bunch of ESPHome/ESP8266 projects, several of which are have been plagued by repeated disconnection during seemingly random times of instability. Sometimes they’ll be fine for days, and then suddenly they start acting up again, and it can…

I’m using connections to my home network to indicate presence of family members primarily using the Ping (ICMP) integration, but with this method, iPhones frequently “go offline” because they don’t respond to these pings when trying to safe power. The…

What’s a Deckel? A Deckel is a lid for a drink. It fits over a glass (like one of those large German Maas mugs or a red solo cup) to identify it as your own and to keep the flies…

tl;dr The ESP-12F ADC pin appears to consistently read higher values at times when the processor is not as busy. I worked around this by taking the average of multiple reads, and discarding any averages where the number of samples…